Weldability

Film-type contaminants may impact joining processes negatively. As a result they can lead to poor welding quality or weak bonds. Appropriate monitoring of components cleanliness commonly requires time consuming, destructive and expensive analysis techniques. These methods do not allow quantitative in-/at-line testing.

Weld seam faults occurred selective when welding components treated with corrosion inhibitors.

Next to corrosion inhibitors, further film contaminations are present on the components surface and must be identified. The main target is to reduce rejects after welding.

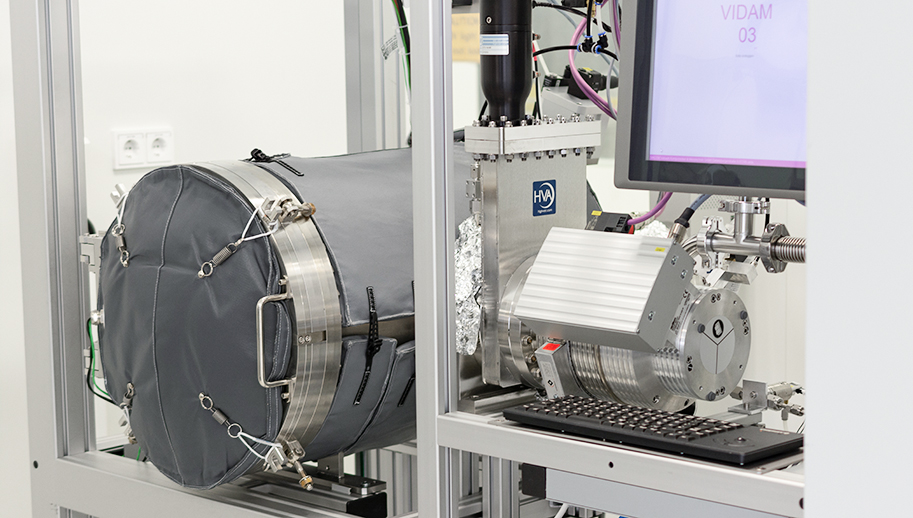

VIDAM® xfine (detection limit absolute 1 µg)

No film-type contaminants were determined on the components. However, different batches of welded parts showed strong fluctuations in the detected amount of corrosion inhibitors. Therefore, process parameters for applying the corrosion inhibitors were monitored while testing the components cleanliness with VIDAM®. Eventually, the applied quantity was stabilized. As a result selective occuring weld seam faults were eliminated and reject rates significantly reduced.