Supplement to ultrasonic wet cleaning

Commonly, film-type contaminants cannot be avoided during the production of components and can affect many processes negatively. In order to reach a sufficient components cleanliness an optimal cleaning process is necessary. Appropriate monitoring of components cleanliness commonly requires time consuming, destructive and expensive analysis techniques. These methods do not allow a quantitative in-/ at-line testing.

A manufacturer of components has to meet and verify certain acceptance criteria. The requested residual dirt level for organics lies below 1 ng / cm2. To satisfy the high purity requirements, a new ultrasonic wet cleaning system was purchased.

Optimization of system parameters in collaboration with manufacturer of components, cleaning systems engineers and TREAMS. The cleaning process provides components which permanently and securely fulfill the acceptance criteria.

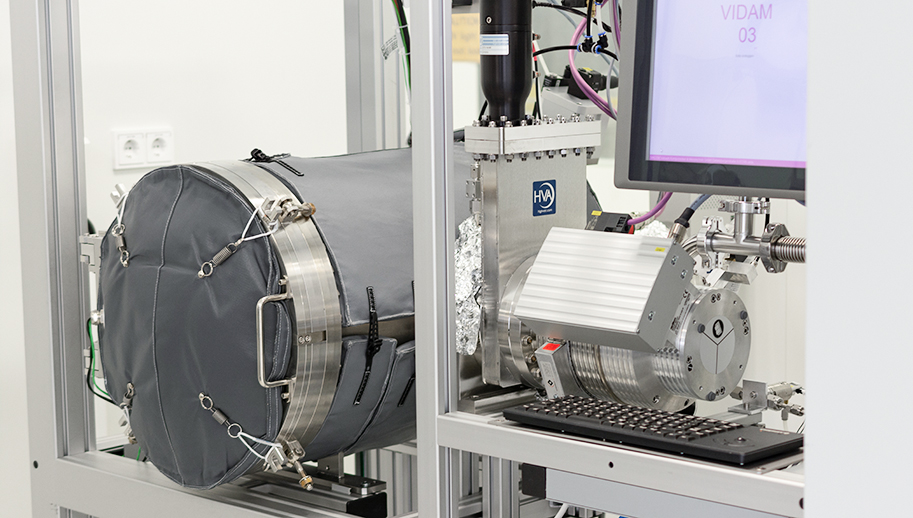

VIDAM® xfine (detection limit absolute 1 µg)

The cleaning process has been optimized and components with the required residual contamination level are generated. Defects were eliminated and reject rates significantly reduced. VIDAM measurements detected an overload of the cleaning system and thereby enable early intervention. The manufacturer of components can continuously fulfil and verify the required acceptance criteria.