Protective coating

Film type contaminations can negatively influence the coating process. For example, they reduce the adhesion of the coating or cause optical defects. Adequate monitoring of component cleanliness is only possible using time-consuming, destructive and costly analysis techniques. Quantitative in-line / at-line testing is not possible with these.

Components sealed with protective coating failed before reaching the specified lifetime. As an effective countermeasure, in addition to conventional cleaning, a tempering process lasting several hours was annealing process was integrated into the production process.

Problem:

The additional tempering process increases manufacturng costs and time.

Film type contamination prevents optimum adhesion of the protective coating. The cleaning process is analyzed in detail with the aim of increasing process reliability, avoiding the cost-intensive annealing process and thus reducing production costs and times.

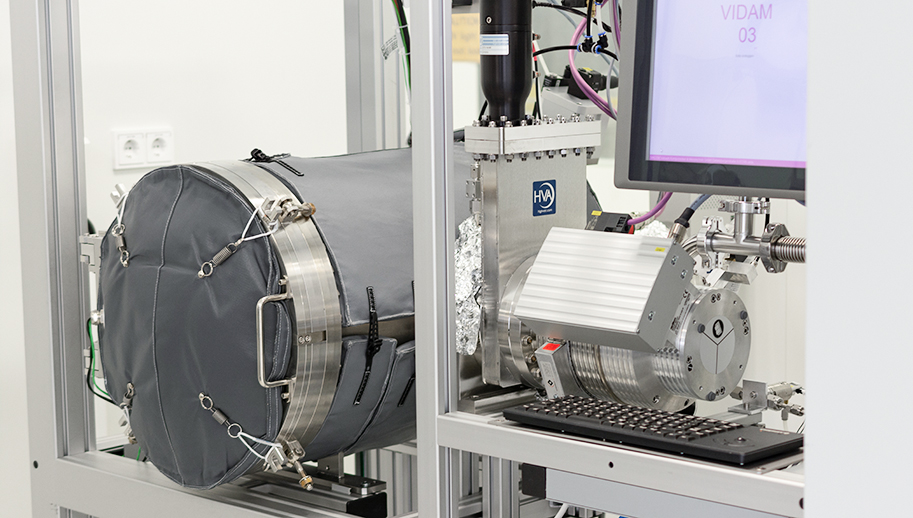

VIDAM® xfine (detection limit absolute 1 µg)

Significant variations in component cleanliness were found after conventional cleaning. The effectiveness of the annealing process was basically confirmed. However, the measurements revealed that optimized cleaning provides sufficiently clean components even without a subsequent annealing process. VIDAM® measurements prior to coating made it possible to save on the annealing process, thus reducing thus reducing production costs and times while increasing process reliability.