Development and manufacturing of state-of-the-art vacuum systems

On the following pages, experience an insight into our state-of-the-art standard system series such as analysis devices, vacuum ovens and thermal vacuum chambers. Our experts will be happy to design such a system according to your requirements. If you are looking for a special solution for a vacuum system in the high purity range, please also contact us.

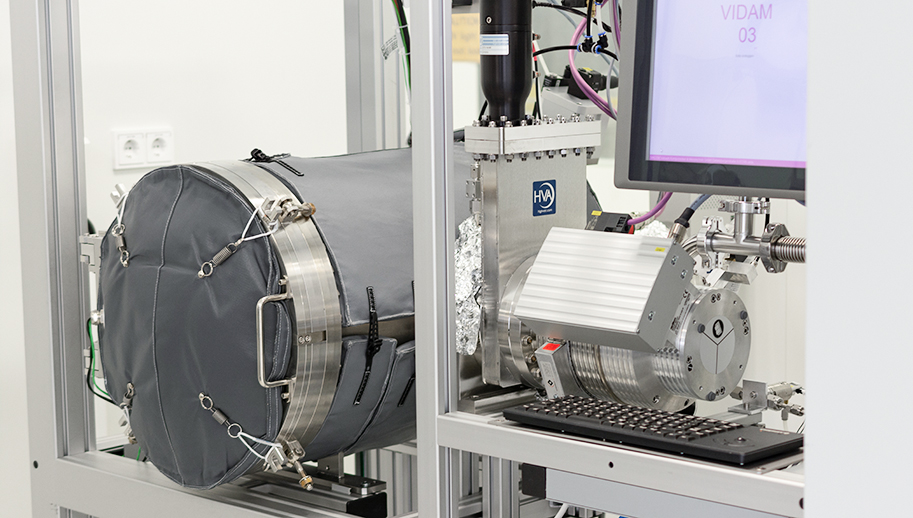

Easy and efficient: Our systems for the determination of cleanliness and outgassing rates

Our systems define today´s standard for the detection and analysis of chemical film-type contaminants and outgassing rates on parts and assemblies. The used technology offers you the possibility to determine the exact cleanliness and outgassing characteristics of your parts.

Advantages of our products

Up to now, adequate monitoring of parts cleanliness was only possible via time-consuming, destructive and/or expensive analytical methods. This changes with our products. Cleanliness becomes available to everyone.

Our analytical devices

- detect film-type contaminants and outgassing rates of the surfaces of individual components or assemblies of any geometry.

- provide quantitative results (mass of residual dirt in g or outgassing rate in mbar*l/s each per surface in cm²) and, thus, prepare the way to determine appropriate limits for sufficient parts cleanliness.

- test non-destructively and without recontamination. Your components can be further processed immediately after testing.

- allow an easy identification of the causes of film-type contamination and enable efficient and targeted process optimisations.

- can be used close to production, i.e. practically in-line.

- are very easy to operate due to the automated measuring process and the intuitive software. After an extensive user training, the system can be operated by each employee.

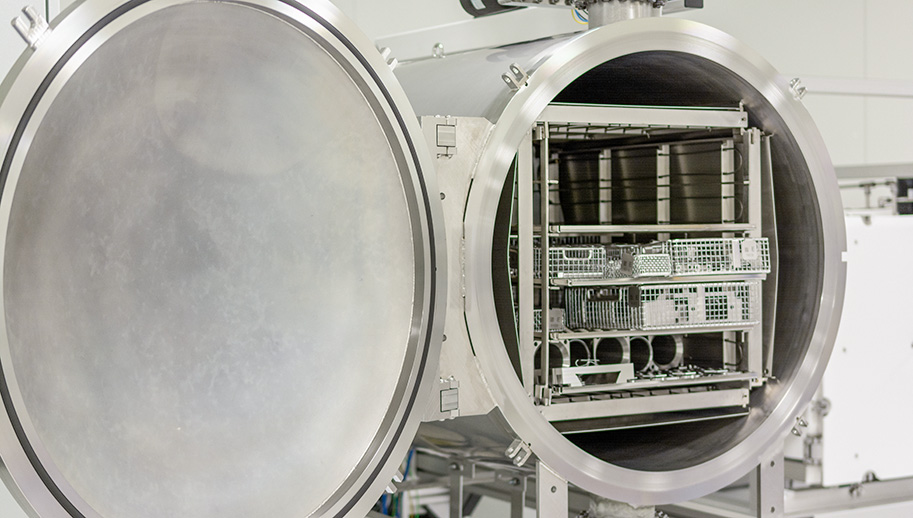

Vacuum baking oven for dry cleaning and outgassing rate reduction:

Optimise your fine and ultra fine cleaning track with our vacuum baking ovens, with the aid of which you can perform a final dry cleaning and remove residual contaminations. It is also possible to reduce outgassing rates via baking processes. The optional integration of a mass spectrometer allows to control the baking process by means of the continous measured value increase simultaneously with the temperature control process.

Thermal vacuum chambers:

Simulate the environmental parameters pressure and temperature of space under controlled conditions. With the help of HeVACool systems your assemblies can be tested and qualified for their suitability.